About Us

Anyang City days a thermal spray materials Co., Ltd. is specialized in thermal spray materials research and development, production, which has an independent legal personality of the high-tech enterprises, the company is located in Anyang City, Henan Province High-tech Zone Jinggangmycin Street, adjacent to the Beijing-Guangzhou Railway and Beijing-Zhuhai Expressway, convenient transportation location. The company has a group of senior research and development, production and technical personnel, in full accordance with international standards of production and quality management, accumulated a wealth of product and production experience!

Produced by thermal spraying ceramic powder, particle size distribution, good liquidity, stable product quality, excellent coating performance, high-quality coatings, long-term storage does not absorb moisture caking. Domestic engaged in thermal spraying processing enterprises, the trial I produced after thermal spraying ceramic powder are instead using my company's products, the long-term use, consistent spoke highly of!

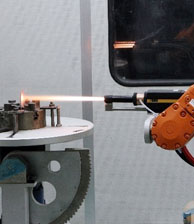

It is the use of heat the coating material is heated to a molten or semi-molten state, and then by means of the flame stream and high-speed.

The gas particles are sprayed onto the coating material the substrate surface, thereby depositing a coating of a certain special features Seed technology.

The gas particles are sprayed onto the coating material the substrate surface, thereby depositing a coating of a certain special features Seed technology.

Twentieth century the 1980s, there has been a first-generation HVOF equipment Jet-Kote;

Particle velocity up to 400m / s or more;

Coating greatly improved bond strength, porosity greatly reduced;

Flame temperature <3000 ℃, the carbide coating small decomposition process;

Aviation kerosene instead of using propane, propylene and oxygen to reduce the cost;

In recent years the use of compressed air instead of oxygen HVAF equipment, tungsten carbide coating better performance.

Particle velocity up to 400m / s or more;

Coating greatly improved bond strength, porosity greatly reduced;

Flame temperature <3000 ℃, the carbide coating small decomposition process;

Aviation kerosene instead of using propane, propylene and oxygen to reduce the cost;

In recent years the use of compressed air instead of oxygen HVAF equipment, tungsten carbide coating better performance.

Low degree of oxidation, tungsten carbide carbon loss near vacuum spraying;

Porosity 1%;

Strength approaching sintering / casting material;

High hardness, good toughness;

Excellent polishing performance, can be polished to a mirror;

High production efficiency, metal 20Kg / h, tungsten carbide 30-40Kg / h;

Spraying process does buildup.

Porosity 1%;

Strength approaching sintering / casting material;

High hardness, good toughness;

Excellent polishing performance, can be polished to a mirror;

High production efficiency, metal 20Kg / h, tungsten carbide 30-40Kg / h;

Spraying process does buildup.

Environmental requirements: Cr6 + carcinogenic, electroplating wastewater pollution.

Some of the requirements for high temperature, corrosion and wear conditions, can not meet the requirements:

The presence of microcracks in hard chrome plating;

The presence of hydrogen embrittlement of hard chrome plating;

Deposition plating process is slow (about 25μm / hour), long process cycle;

Plated workpiece size is limited dimensions of the plating tank;

The presence of microcracks in hard chrome plating;

The presence of hydrogen embrittlement of hard chrome plating;

Deposition plating process is slow (about 25μm / hour), long process cycle;

Plated workpiece size is limited dimensions of the plating tank;

Cost factor: For larger size, requires coating of the workpiece, the cost is relatively high;

The higher environmental requirements, waste discharge costs.

In recent years, countries have carried out research into alternative hard chromium plating.

Among the many methods, HVOF made a major breakthrough,

Substantially overcomes the aforementioned problems of hard chrome plating,

Get a wider range of applications.

The higher environmental requirements, waste discharge costs.

In recent years, countries have carried out research into alternative hard chromium plating.

Among the many methods, HVOF made a major breakthrough,

Substantially overcomes the aforementioned problems of hard chrome plating,

Get a wider range of applications.